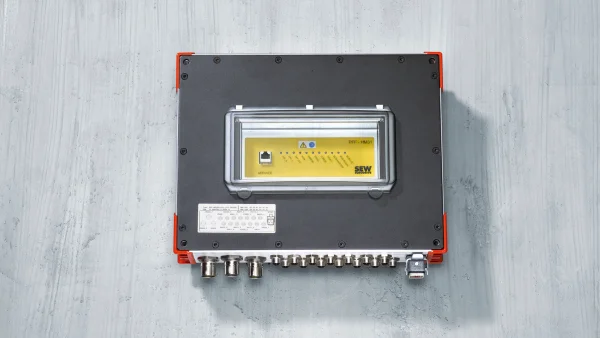

With its freely programmable drive and application inverter, MOVIPRO® ADC brings your production system architecture up to date – regardless of whether you use stationary or mobile materials handling technology.

Compact and freely programmable controller for decentralised drive technology

Do your mobile and stationary materials handling systems need drive systems that are compact and resistant to vibration? Do you require perfectly synchronised multi-axis movements? Are integrated safety functions an absolute must for you?

Our decentralised MOVIPRO® ADC drive inverter for application and positioning control meets all of these requirements, and more: Because it can be programmed freely (in accordance with IEC 61131-3 and PLCopen), you can implement application-specific and complex functions in a flexible way. In addition to multi-axis synchronisation, precise, local coordination of multiple actuators and sensors is also possible.

This makes MOVIPRO® ADC the optimum solution for decentralised drive technology in the following situations:

- If vast installations need to be equipped with and automated by electrical drives

- If you need to ensure the precise synchronisation of multiple axes within your system, or coordinate multiple sensors and actuators

- If your process requires advanced safety functions

- If your system is based on reusable modular functions

- If your process requires a compact and integrated drive controller

- If you want to implement optimal speed control and precise positioning

- If you plan to manage I/Os and encoders locally

- If quick diagnostics and maintenance are important to you

- If you want a complete drive solution in one package

With the MOVIPRO® ADC drive, positioning and application controller, you can build the foundations for an open and flexible system architecture – whether you're designing a new system or modernising an old system. We guarantee you functional compatibility with existing control cabinet applications. When combined with our MOVITOOLS® MotionStudio, you can benefit from an integrated software environment for your entire engineering process – from setup and diagnostics right through to maintenance.

Get in touch with us.

- Our experts understand your industry and your requirements.

- Our global network ensures we are close wherever and whenever you need us.

- We have the expertise and the tools to provide optimum support and advice.

Your benefits

-

Individual control

The inverter can be programmed freely and comes with standardised application modules for multiple drive and positioning tasks. -

Seamless coordination of multi-axis movements

Thanks to intelligent synchronisation and the ability to coordinate multiple sensors and actuators at local level. -

Reduction in idle time

Thanks to decentralised engineering and easy connectivity, allowing quick retrofitting of systems and a reduction in wiring errors. -

Increased consistency

Thanks to an integrated installation concept for the entire materials handling technology process and use of the same software tools for operation and diagnostics -

Reduction in complexity

Thanks to communication via common fieldbus systems and support for a wide range of motors (asynchronous and synchronous).

Features

Compact performance for decentralised applications

- Power range of 2.2 kW to 15 kW

- Speed control and positioning

- Optional encoder feedback for motors and tracks

- Integrated brake control with different brake voltages

- Optional regenerative power supply

- Fieldbus interfaces: PROFIBUS, PROFINET, PROFIsafe, EtherNet/IP, Modbus/TCP, DeviceNet

- Integrated inputs/outputs 12 DI + 4 DIO (DI=Digital in, DIO=Digital in/out)

- Optional RS485, SBus, and SBUSplus interfaces for external actuators and sensors

- Plug-in interfaces for energy, motors (power), and encoders (signals)

- Local memory for parameters

- IP54 protection type

- Robust aluminium housing

- Optional maintenance switch

- Optional, removable connection unit for linear power bus

- Safe Torque Off (STO) up to PL d according to EN ISO 13849-1

- Optional: Secure PROFIsafe bus system

- Optional: Safe brake control (SBC)

Technical data

- Power range 2.2 to 15 kW

- Size BG0: 2.2 kW

- Size BG1: 4 kW, 7.5 kW

- Size BG2: 11 kW, 15 kW/operation without fan up to 11 kW

- 12 DI + 4 DIO (DI=digital in, DIO=digital in/out)

Areas of applications

Use of MOVIPRO® ADC application inverter for decentralised system designs

For integrated, field-oriented drive solutions, MOVIPRO® ADC focuses primarily on conveyor and machine applications in the automotive industry, production logistics, and intralogistics.

- Scissor lift tables

- Lifting/lowering conveyors

- Lifting stations with lifting tables

- Conveyor trolleys

- Feeder conveyors

- Rotary distributors

- Rotary indexing tables

- High-speed horizontal conveyors with positioning

- Transfer systems on rails

- Multi-axis handling gantries

Accessories

Accessories for convenient handling

- Power interface for convenient connection to power supply

- Sensor/actuator box for connecting up to 8 sensors or actuators

- External braking resistors for applications with 4Q drive operating mode for dissipating regenerative power to MOVIPRO®

- STO jumper plug for deactivating MOVIPRO® safety functions, if required

- Mounting accessories: Handles and external mounting bracket fan components for MOVIPRO® ADC size BG 2, 11 kW (fan groups are obligatory for 15 kW and are pre-assembled)

Functional extensions for complete systems

MOVIPRO® version for controlling MAXOLUTION® system solutions

Specific customisations and extended functions combine to provide MOVIPRO® a compact drive and system inverter with safety controller for MAXOLUTION® system solutions

Different features

- Power range of 0.75 kW to 22 kW

- Integration of up to 3 axes

- Control and supply or external actuators (auxiliary axes)

- Fieldbus and network interfaces

- Integrated DIO

Extended functions

- Positioning and navigation: Precise track positioning and inductive or visual track guidance

- Communication via WNI (wireless network interface): Contactless communication for slotted waveguides, radiating cables, and radio

- Power supply: Contactless energy transfer system with MOVITRANS® for mobile systems

- Energy management: Energy storage device with quick charging function

Integrated functional safety

- The decentralised safety controller MOVISAFE® HM31 meets the safety requirements of the MAXOLUTION® system solutions

- Hardware assignment

- Certification

- Communication

Software alternatives

- Configurable system software MOVIVISION®

- Custom programming with MOVI-PLC® in accordance with IEC 61131 and PLCopen for system-specific or complex functions

- Safety functions can be programming or configured using the SILworX graphical user interface